Stitching the Future: How CNNs are Revolutionizing Quality Control in Garment Manufacturing

Sewing quality in every stitch with Convolutional Neural Network (ConvNet/CNN)

A picture is worth a thousand words. It has been an age old saying which is proving to be far more true in the age of Artificial Intelligence. Today, with the advances in machine learning a picture is not just an image but a multi-layered dataset containing innumerable data points. Researchers have been working tirelessly to make applications and models that can replicate human actions. One such field of research is Computer Vision.

Computer Vision is a research endeavor that enable machines to see things and process that information as human eye and brain would. It aims to provide the machines with decision-making abilities based on the information they see.

Numerous scientific researches have been undertaken and algorithms written to empower machines with ability to undertake tasks such as Image and Video recognition, Image Analysis and Classification, Media Recreation, Recommendation Systems, Natural Language Processing, etc. The success in this area is primarily achieved due to Convolutional Neural Network (ConvNet/ CNN) algorithm.

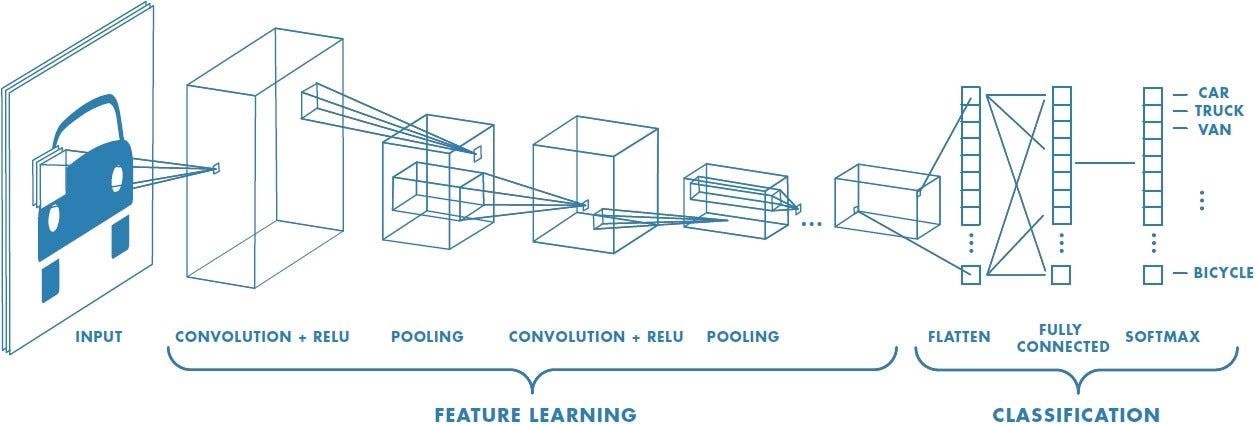

CNN is a Deep Learning algorithm that taken an image as an input and collects data points on various differentiating aspects. It is made up of various multiple layers including convolutional layers, pooling layers, and fully connected layers. This makes it well suited for image recognition and processing tasks.

Diagram: Convolutional Neural Networks

Source: A Comprehensive Guide to Convolutional Neural Networks — the ELI5 way, Sumit Saha, Towards DataScience

Keeping aside the technicalities of the algorithm, this just seems straight out of a sci-fi. However, in real world too, CNN has great applicability. A practical use- case which we propose is to train this algorithm to identify quality defects in garment manufacturing industry. Globally, garment manufacturing industry is valued at USD 652.49 billion in 2023 as per Research and Markets –Apparel Global Market Report 2023. It is expected to grow at CAGR of 6.2% from 2023 to 2027. Garment industry is a complex and diverse industry and product differentiation relies heavily on quality of the output. The industry deploys extensive quality control measures and checks, most of which are carried out manually. Preventing, detecting and dealing with the quality defects incurs quality cost. The quality cost can be as high as 20-25% of the total manufacturing cost and thus significantly impacts profit margins and put brands at risk.

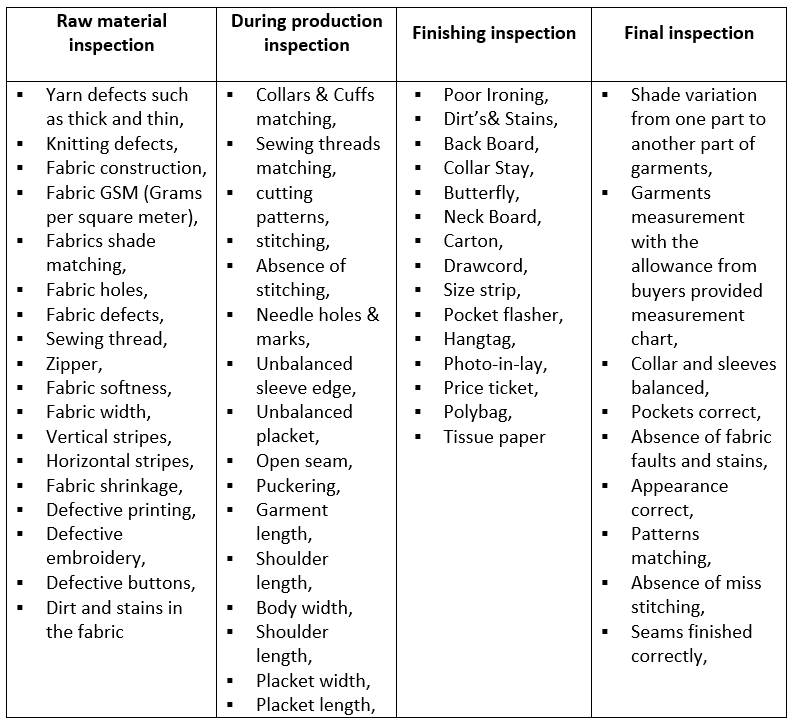

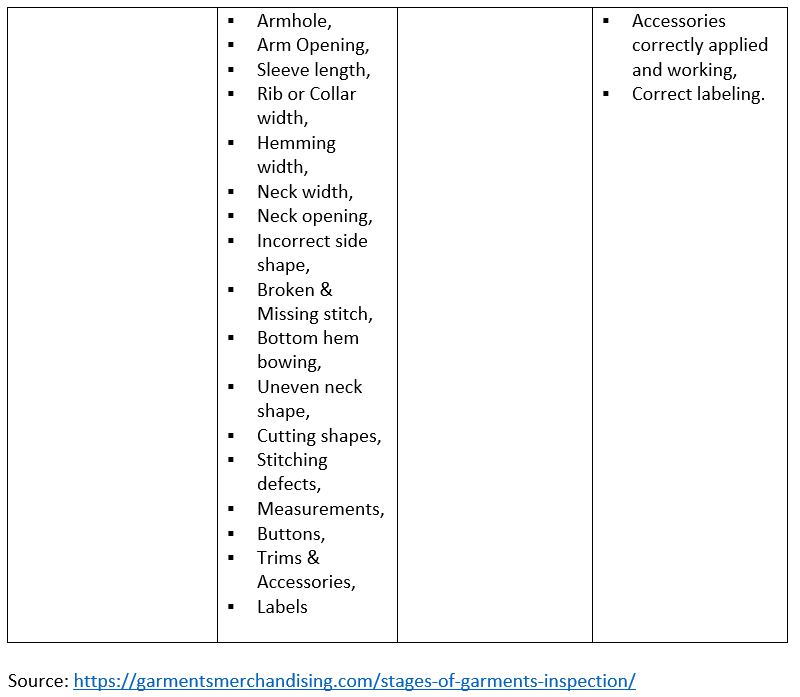

Quality control is undertaken at various steps on the manufacturing process. Quality of fabric, threads, zipper, buttons, sewing, dyeing all impact the quality of end product. Physical and chemical quality tests are conducted at various stages.

Table: Inspections at different stages of garment manufacturing

At present, most of the inspection work is done manually with naked eye. CNN’s Deep Learning algorithms can be trained to study the various criteria of quality control. Garment images can be uploaded and the algorithm can break it down into various layers and gather datapoints. These data-points can be matched with the standards and informed decisions about quality of product can be made.

If the CNN algorithm can be trained to carry out quality control, it can revolutionize the garment industry and create value worth billions of dollars.